Alphacam Turning - 2-Axis To 5-Axis Lathe Turning With Reliable NC Code

Alphacam is a leading CAM solution for turning from 2-Axis through to 5-Axis programming. The emphasis behind the development of Alphacam is to provide our customers with productivity, reliability and flexibility.

Core Foundation

All Alphacam modules are built using one core foundation which includes geometry creation commands such as line, arc, circle, rectangle, polygon, ellipse, spline and polyline together with surface creation options. Other features include intelligent snapping functions such as end, mid, center, intersect, tangent, quadrant and auto. Import options for DXF, DWG, IGES and a variety of solid model formats ensure compatibility with other CAD systems. There are also various geometry editing functions including undo, redo, move, copy, rotate, mirror, scale, break, trim, explode, join, extend, fillet, chamfer and offset. All modules have user defined tool and material libraries controlling many of the important machining parameters such as tool direction, automatic lead in and lead out, corner cut options (straight, roll round or loop), G41/42 tool compensation and automatic calculation of speeds and feeds.

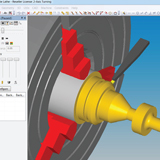

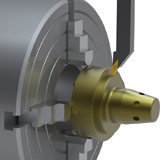

Turning

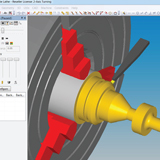

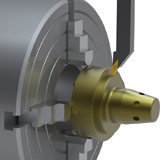

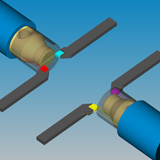

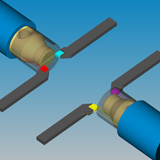

All standard 2-axis turning operations are quick and easy to generate using Alphacam, with support for both linear and canned cycle NC code. Along with an extensive standard library, any shape and size tool can be created within Alphacam, the tip and holder of which are constantly checked to avoid fouling of the part. Both twin turret and sub-spindle operations are supported by the Advanced Lathe modules to which automatic and manual synchronization can easily be applied. From simple 2D slots and holes to the simultaneous 5-Axis machining of complex 3D surfaces and Solids using driven tools, Alphacam makes it easy.

Multi-Axis Machining

Work plane support for machining centers with 4 and 5-Axis indexing capability is made simple with Alphacam. Parts can be dragged and dropped onto a fixture, their datum set and machining sequence automatically optimised. The advanced solid simulation, with full machine build, within Alphacam means that the tool path can be verified before it reaches the machine tool. Clamp and fixture collision detection, support for work co-ordinate offset tracking and plane rotation means that the NC code generated is right first time.

Post Processors

With manufacturers facing ever increasing global competition, it is essential to maintain maximum machinery efficiency to ensure optimal production throughput. Having an optimised link between Alphacam and your CNC machines, through the use of post processors, is a key component in attaining this efficiency. Having developed post processors for virtually every machine control in use today, Alphacam has the knowledge and experience to fine tune your CNC output ensuring maximum yield and quality in the shortest possible time